A cikin injunan konewa na ciki tare da bel ɗin bel na tsarin rarraba gas, ya zama dole don tabbatar da daidaitaccen matsayi na bel da kwanciyar hankali yayin aiki.Ana warware waɗannan ayyuka tare da taimakon rollers kewaye, manufar, ƙira da maye gurbin wanda aka bayyana dalla-dalla a cikin wannan labarin.

Menene abin nadi na wucewar lokaci?

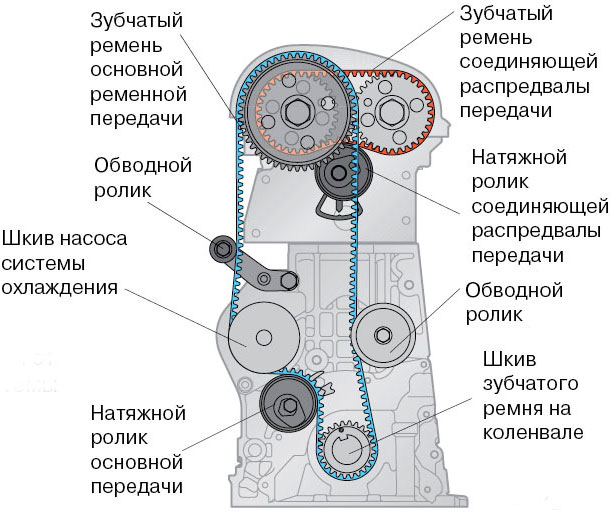

Kewaya (tallafi, tsaka-tsaki, parasitic) abin nadi shine ƙarin kashi na bel drive na injin rarraba iskar gas (lokaci), juzu'in juzu'i na ƙaramin diamita, ta inda ake kewaya bel ɗin lokaci a wani wuri (ko maki). ).

Nadi na kewayawa lokaci yana magance matsaloli da yawa:

• Canza bel ɗin tafiya (juya zuwa kusurwar da ake buƙata) daidai da wurin da ke cikin camshaft pulleys da haɗe-haɗe;

• Kawar da rawar jiki na rassan bel tare da tsayi mai tsayi;

• Tsayar da bel na lokaci yayin aiki, rigakafin abubuwan da suka faru, zamewa, da dai sauransu;

• Gaba ɗaya rage amo na hanyar rarraba iskar gas.

A cikin bel ɗin lokaci, yawanci ana amfani da abin nadi na kewayawa guda ɗaya, ƙasa da sau biyu, amma yawancin injunan ƙarami na zamani ba su da waɗannan sassa kwata-kwata.A lokaci guda, bai kamata mutum ya rikitar da abin nadi na kewayawa tare da wani nau'in irin wannan ba - abin nadi na tashin hankali.Nadi na tashin hankali yana ba da mahimmancin tashin hankali na bel, yana hana shi daga zamewa da lalacewar injin da ke da alaƙa, kuma yana aiwatar da ayyukan abin nadi a kan hanya.A nan gaba, za mu yi magana game da kewaye rollers.

Nau'i da ƙira na lokaci-lokaci rollers kewaye

Ba tare da la'akari da nau'in ba, duk rollers na kewaye ana shirya su ta hanya ɗaya.Tushen abin nadi shine mai ɗaukar nauyi, akan zobe na waje wanda aka danna ja.Ƙaƙwalwar radial ne (yana jin kawai lodin da aka jagoranta tare da radius), ƙwallon ƙafa ko abin nadi, na iya zama jere ɗaya na yau da kullun ko faɗin jeri biyu.Za'a iya rufe ƙarshen fuska tare da murfin ƙarfe ko hannun riga don kariya daga datti, ƙura, ruwa da ruwa mai fasaha.Jul ɗin yana da hatimin ƙarfe ko robobi mai ƙarfi, wanda ba ya rabuwa, dangane da nau'in injin, yana da faɗi da diamita daban-daban.

Rollers na ketare na iya samun juzu'in da aka yi da kayan daban-daban:

• Karfe - aluminum gami ko karfe;

• Filastik.

Misalin tuƙi mai ɗaukar lokaci tare da rollers na kewayawa biyu na diamita daban-daban

A halin yanzu, ana amfani da rollers na filastik da yawa, suna da rahusa fiye da na ƙarfe, yayin da suke samar da ƙaramar amo da rage yawan nauyin tsarin.Filastik abu ne da za a sawa, amma albarkatun filastik na zamani na zamani yana da kyau, galibi suna yin hidima ga duka tazarar sabis (tsakanin maye gurbin bel).

Ana amfani da rollers na ƙarfe a cikin injuna masu ƙarfi da ɗorawa sosai, wanda a ciki yana da mahimmanci don tabbatar da amincin tafiyar lokaci a kowane yanayi.

Rollers na iya samun jakunkuna tare da nau'ikan saman aiki daban-daban (hanyoyin tsere):

• Mai laushi - filin aiki yana da santsi, ba shi da wani rashin daidaituwa;

• Corrugated - farfajiyar aiki tana da tsagi na tsayin daka na zurfin zurfi, wannan ƙirar yana rage wurin tuntuɓar ƙwanƙwasa tare da bel;

• Haƙori - saman aiki yana ɗauke da hakora masu jujjuyawa, wannan juzu'i ne mai jujjuyawa kyauta.

A lokaci guda kuma, ana iya yin rollers masu santsi da tarkace da filastik da ƙarfe, kuma masu haƙori na ƙarfe ne kawai - ƙarfe ko aluminum gami.

Abin nadi mai haƙori

Ana shigar da rollers masu laushi da tsinke ta hanyar da bel ɗin ya rufe su da gefen bayansa (mai laushi).Ana shirya rollers masu haƙora ta hanyar da bel ɗin ya rufe su da gefen aiki (haƙori).Sauya rollers na nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau’in nau'in nau'in nau'in nau'in nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i)) ya zama abin karɓa ba za a yarda da shi ba, saboda wannan yana canza halayen tsarin gaba ɗaya kuma yana cike da lalacewar injin.

A ƙarshe, ƙwanƙwasa abin nadi, ba tare da la'akari da nau'in ba, na iya samun nau'i biyu:

• Ba tare da turawa ba;

• Tare da ƙwanƙolin turawa.

A cikin akwati na biyu, ƙwanƙwasa a gefe ɗaya ko biyu yana da ƙulla na ƙananan tsayi waɗanda ke hana bel daga zamewa.A kan robobi masu santsi na filastik da ƙarfe, abin wuya, a matsayin mai mulkin, yana samar da raka'a ɗaya tare da ja, an buga shi, jefa ko juya.A kan rollers masu haƙori, ana iya yin abin wuya a ɗaya ko duka biyun a cikin nau'i na zobe masu cirewa, waɗanda aka saka lokacin da aka sanya abin nadi akan injin.

Shigar da nadi kewaye a kan injin ana aiwatar da shi ta hanyoyi biyu:

• Kai tsaye zuwa shingen injin;

• Amfani da keɓan sashi.

A cikin akwati na farko, abin nadi tare da ɗaukarsa yana kan wani dandali na musamman da aka samar akan toshe injin kuma an gyara shi tare da kusoshi guda ɗaya (ta hanyar wanki na ƙara diamita).A cikin akwati na biyu, an saita abin nadi a kan madaidaicin, wanda, bi da bi, an ɗora shi akan toshe injin tare da kusoshi biyu ko fiye.

Zaɓi, sauyawa da aiki na rollers kewaye da lokaci

Rollers Kewaye suna lalacewa yayin aiki kuma suna buƙatar maye gurbin - ana aiwatar da wannan aikin lokaci guda tare da maye gurbin bel ɗin lokaci da abin nadi na tashin hankali.Duk waɗannan sassa, a matsayin mai mulkin, ana sayar da su a cikin kit, don haka babu buƙatar duba daban don abin nadi da fasteners don shi.Lokacin siyan bel da rollers, ya kamata ku yi la'akari da shawarwarin masana'antun injin kuma zaɓi sassan nau'ikan nau'ikan da suka dace da lambobi.

A wasu lokuta, abin nadi na iya lalacewa ko kasa gaba daya.Mafi sau da yawa, matsaloli suna tasowa a cikin ɗaukar hoto, wanda a cikin yanayin ƙarar hayaniya ke bayyana yayin aikin injin.Abin nadi yana haifar da matsaloli kadan akai-akai.A kowane hali, dole ne a maye gurbin abin nadi, saboda wannan kuna buƙatar siyan sabon sashi bisa ga umarnin masana'anta kuma kuyi aiki daidai da umarnin don gyarawa da kiyaye wannan motar ta musamman.

Yayin aiki, abin nadi na kewaye baya buƙatar kulawa ta musamman, yawanci wannan ɓangaren yana aiki kullum cikin tazarar sabis kuma baya haifar da matsala.

Jiki da ruwan tabarau na fitilun fitila suna da alama tare da manyan halayensa da nau'ikan fitulun da za'a iya shigar dasu.Shigar da wasu hanyoyin haske ba a yarda da shi ba (tare da keɓancewa da yawa), wannan na iya canza halayen fitilun mota, kuma a sakamakon haka, abin hawa ba zai wuce dubawa ba.

Batutuwa na zaɓi, sauyawa da aiki na fitilun mota

Don zaɓar sabon na'urorin gani, yana da muhimmanci a yi la'akari da ƙira, fasali da halaye na tsofaffin samfurori, da kyau ya kamata ku saya fitilar mota na wannan samfurin.Idan muna magana ne game da fitilun hazo ko fitilun bincike da fitilun binciken da ba a kan motar ba, to a nan ya kamata ku yi la'akari da yiwuwar shigar da waɗannan na'urori akan motar (kasancewar madaidaicin madaidaicin, da dai sauransu) da halayen su.

Ya kamata a biya kulawa ta musamman ga zaɓin fitilun mota.A yau, yawanci ana gabatar da su a cikin nau'i biyu - tare da m (fararen fata) da ɓangaren rawaya na siginar juyawa.Lokacin zabar fitilun fitila tare da ɓangaren siginar siginar rawaya, kuna buƙatar siyan fitila tare da kwan fitila mai haske, lokacin zabar fitilun fitila tare da ɓangaren siginar farar fata, kuna buƙatar siyan fitila tare da kwan fitila mai rawaya (amber).

Ana yin maye gurbin fitilolin mota bisa ga umarnin aiki da gyaran mota.Bayan maye gurbin, ya zama dole don daidaita fitilun fitilun bisa ga umarnin guda ɗaya.A cikin mafi sauƙi, ana yin wannan aikin ta amfani da allo - jirgin sama na tsaye tare da alamomi wanda aka nuna alamar fitilun, bango, ƙofar gareji, shinge, da dai sauransu na iya aiki a matsayin allo.

Don ƙananan ƙananan ƙirar Turai (tare da katako mai asymmetric), wajibi ne don tabbatar da cewa iyakar babba na ɓangaren kwance na hasken haske yana kusa da tsakiyar tsakiyar fitilun.Don tantance wannan nisa, zaku iya amfani da dabara mai zuwa:

h = H–(14×L×H)/1000000

inda h shine nisa daga axis na fitilolin mota zuwa saman iyakar tabo, H shine nisa daga saman titi zuwa tsakiyar fitilolin mota, L shine nisa daga mota zuwa allo, naúrar ma'auni shine. mm.

Don daidaitawa, wajibi ne a sanya motar a nesa na mita 5-8 daga allon, ƙimar h ya kamata ya kwanta a cikin kewayon 35-100 mm, dangane da tsayin motar da wurin da fitilun ta.

Don babban katako, ya zama dole don tabbatar da cewa tsakiyar wuraren hasken ya ta'allaka ne da rabin nisa daga axis na fitilun fitilun da kan iyakar ƙarancin haske.Har ila yau, ya kamata a bitar da gatari na fitilun fitilun gaba da gaba, ba tare da karkata zuwa ga bangarorin ba.

Tare da zaɓin da ya dace da daidaitawa na fitilun mota, motar za ta karbi kayan aikin haske masu kyau wanda ya dace da ka'idodin ka'idoji kuma yana tabbatar da tsaro a kan hanya lokacin tuki a cikin duhu.

Lokacin aikawa: Agusta-22-2023