A cikin kowane injin konewa na ciki na piston akwai ɓangaren da ke haɗa piston zuwa saman saman sandar haɗi - fil ɗin piston.Komai game da fitilun piston, fasalin ƙirar su da hanyoyin shigarwa, kazalika da zaɓin daidai da maye gurbin nau'ikan fil daban-daban an bayyana su dalla-dalla a cikin labarin.

Menene fil ɗin piston

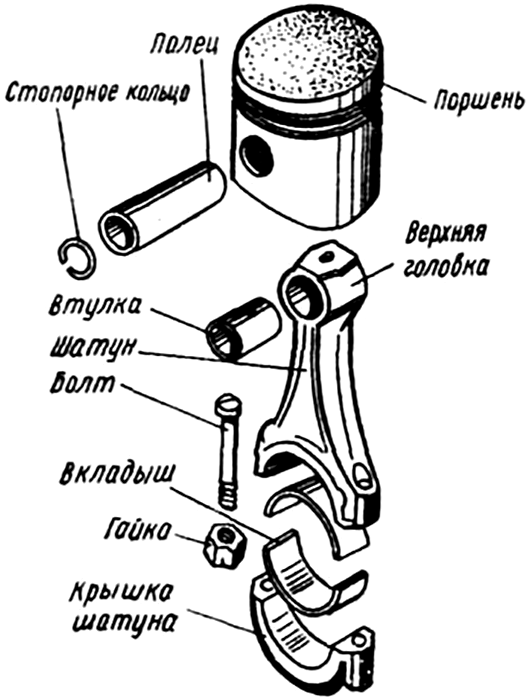

Piston fil (PP) wani bangare ne na rukunin piston na injin konewa na ciki;karfe m Silinda, tare da taimakon abin da piston da haɗa sanda suna hinged.

A cikin injunan konewa na ciki, watsawa da jujjuyawar sojojin da ke tasowa daga konewar cakuda man-iska a cikin silinda ana aiwatar da su ta hanyar ƙungiyar piston da injin crank.Babban sassan waɗannan tsarin sun haɗa da fistan da igiya mai haɗawa tare da haɗin gwiwar hinge, saboda haka yana yiwuwa a karkatar da igiya mai haɗawa daga madaidaicin piston lokacin da yake tsakanin manyan matattu na sama da ƙananan (TDC da TDC).Ana aiwatar da haɗin haɗin haɗin piston da igiya mai haɗawa ta amfani da sashi mai sauƙi - fil ɗin piston.

Piston fil yana magance ayyuka guda biyu:

● Yana aiki azaman maɗaukaki tsakanin fistan da sandar haɗi;

● Yana ba da canja wurin ƙarfi da juzu'i daga sandar haɗi zuwa fistan lokacin fara injin kuma daga piston zuwa sandar haɗawa lokacin da injin ke gudana.

Wato, PP ba kawai yana haɗa piston da sanda mai haɗawa cikin tsarin guda ɗaya (wanda kuma ya haɗa da crankshaft), amma kuma gabaɗaya yana tabbatar da haɗin gwiwar ƙungiyar piston da injin crank injin.Don haka, duk wani rashin aiki ko sa yatsa yana yin illa ga aikin gabaɗayan rukunin wutar lantarki, yana buƙatar gyara cikin gaggawa.Amma kafin siyan sabbin fil ɗin piston, yakamata ku fahimci ƙirar su da wasu fasalulluka.

Nau'o'i, na'ura da halaye na fil ɗin piston

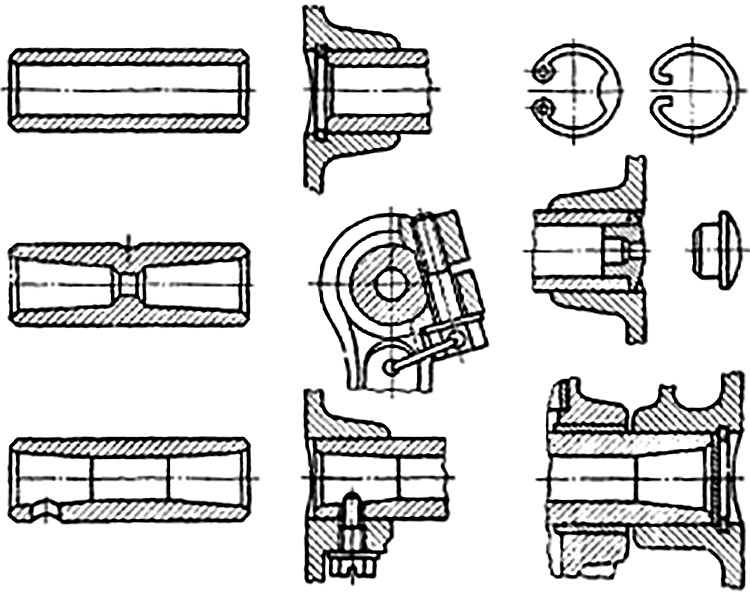

Duk fitattun fistan da ake amfani da su a halin yanzu suna da ainihin ƙira iri ɗaya: gabaɗaya, sandar ƙarfe ce mara ƙarfi tare da katangar bakin ciki da aka sanya a cikin shugabannin fistan da kuma saman sandar haɗin gwiwa.A ƙarshen fil, ana cire chamfers (na waje da na ciki), wanda ke tabbatar da sauƙin shigarwa na sashi a cikin fistan ko sandar haɗi, kuma yana hana lalacewa ga wasu sassa idan an yi hulɗa tare da su.

A lokaci guda, ana iya yin abubuwa daban-daban na taimako a cikin yatsu:

● Kawo bangon ciki cikin mazugi daga tsakiya zuwa waje don haskaka yatsa yayin da yake kiyaye ƙarfinsa;

● Belin zobe na ciki a tsakiyar ɓangaren yatsa don taurare shi;

● Ramukan juzu'i na gefe don tsayayyen fil a cikin maigidan piston.

Piston fil an yi su ne da carbon tsari mai laushi (15, 20, 45 da sauransu) da wasu gami (yawanci chromium 20X, 40X, 45X, 20HNZA da sauransu).Ƙarshen waje da ƙaramin bel a ƙarshen sassan da aka yi da ƙananan karafa ana yin carburized kuma an kashe su zuwa zurfin 1.5 mm har sai an kai taurin 55-62 HRC (yayin da Layer na ciki yana da taurin a cikin kewayon 22- 30 HRC).Sassan da aka yi da matsakaicin ƙarfe na carbon yawanci ana taurare da igiyoyi masu ƙarfi.Bayan maganin zafi, ana yin amfani da waje na PP zuwa nika.Ƙarƙashin ɓangaren yana ba da juriya na waje don sawa, yayin da danko na bangon ciki na ciki yana riƙe da ikon yatsa don tsayayya da nauyin girgiza da girgiza.Nikawar saman yana kawar da wuraren da ke da damuwa mai haɗari, wanda a lokacin aikin injin zai iya haifar da kullun, taurin kai ko ma lalata sassa.

Tsarin fistan na al'ada tare da sandar haɗi

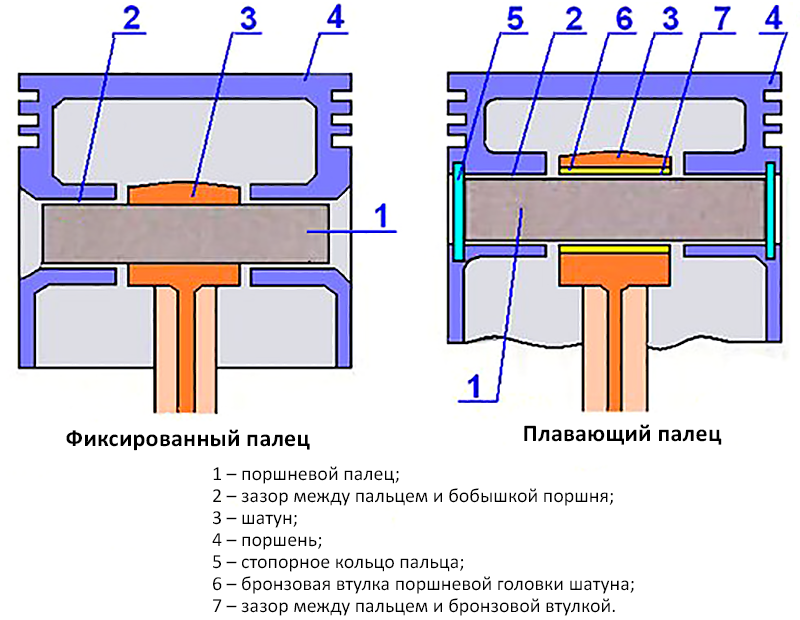

Kamar yadda aka riga aka nuna, piston fil yana cikin fistan da kuma saman saman sandar haɗi, yana haɗa waɗannan sassa zuwa tsarin guda ɗaya.A cikin fistan na wannan bangare akwai kari guda biyu tare da ramukan masu juyawa - shugabanni.Akwai zaɓuɓɓukan ƙira guda biyu don hinge tsakanin piston da sanda mai haɗawa:

● Tare da yatsa "mai iyo";

● Tare da danna yatsa cikin sandar haɗi.

Ana aiwatar da makirci na biyu kawai: a cikin wannan yanayin, an danna PP a cikin babba (guda ɗaya) na sandar haɗin gwiwa, wanda ke hana motsin axial, kuma a cikin shugabannin piston yana tare da wani tazara. , wanda ke ba da damar kunna piston dangi zuwa PP yayin aiki na naúrar wutar lantarki a cikin kowane yanayi.Har ila yau, rata yana ba da man shafawa na sassan shafa (ko da yake saboda ƙananan rata, yatsa da saman shugabannin da ke hulɗa da shi ko da yaushe suna aiki a cikin rashin isasshen yanayin lubrication).An yi amfani da wannan makirci a kan motoci na gida Vaz-2101, 2105, 2108, ana amfani dashi a kan samfurori na zamani na samar da waje.

Tsarin yatsa "mai iyo" ya fi rikitarwa, saboda yana da sassa masu taimako da yawa.A cikin wannan makirci, an shigar da PP tare da ƙaramin rata a cikin sassan biyu - duka a cikin shugabannin piston da kuma a saman sandar haɗin kai, wannan yana tabbatar da jujjuyawar ta kyauta yayin aikin injin.Don hana ƙaurawar axial na yatsa, ana amfani da zoben riƙewa na bazara, waɗanda ke cikin ramuka a cikin shugabanni - suna aiki azaman tasha ga PP, suna hana shi faɗuwa.Za a iya yin zoben da waya ta bazara tare da madauwari mai madauwari ko kuma an buga ta daga karfen takarda.A cikin akwati na ƙarshe, sassan suna da ɓangaren giciye na rectangular, kuma ana ba da ramuka don kayan aiki a duka iyakar don sauƙi na shigarwa da cire zoben.

A wasu lokuta, ana amfani da fungi masu kulle ko matosai, an yi su da ƙarfe mai laushi, don haka ba sa lalata madubi na Silinda lokacin da yake hulɗa da shi.Ana amfani da filogi a cikin injunan bugun jini guda biyu tare da wani tsari na ci da tagogin shaye-shaye, yana hana kwararar iskar gas maras so a tsakaninsu.Wani lokaci ana amfani dashi don gyara sashin tare da dunƙule a cikin ƙananan ɓangaren maigidan kuma a cikin rami a ƙarshen PP.

Kafaffen fistan piston mai iyo

PP, ba tare da la'akari da hanyar shigarwa ba, na iya samun ƙaura dangane da axis na piston, ya kai daya da rabi ko fiye da millimeters.Wannan ƙaura an yi niyya ne don rage ɗorawa mai ƙarfi wanda aka sa fistan, PP da shugaban sanda mai haɗawa yayin TDC da TDC.Piston a cikin motsi zuwa TDC da TDC yana danna kan bango ɗaya na Silinda, wanda kuma yana kaiwa ga danna PP a bango ɗaya na ramukan cikin shugabannin.A sakamakon haka, akwai sojojin da ke da wuya a juya PP a cikin sassan mating, kuma lokacin wucewa TDC da TDC, juzu'i na iya faruwa ba zato ba tsammani - wannan yana faruwa tare da bugun jini, wanda aka nuna ta hanyar ƙwanƙwasawa.Ana kawar da waɗannan abubuwan daidai ta hanyar shigar da PP a cikin fistan tare da wasu ƙaurawar axis.

Yadda za a zaɓa da maye gurbin fil ɗin piston

A lokacin aikin injin, musamman ma a cikin hanyoyi daban-daban, yatsunsu suna fuskantar manyan lodi, sun ƙare, suna iya lalacewa kuma suna buƙatar maye gurbin.Ana nuna buƙatar maye gurbin yatsunsu ta hanyar lalacewa na matsawa da raguwa a cikin halayen motsa jiki na injin, wanda kuma yana nunawa ta hanyar ƙwanƙwasawa.

Gyara naúrar wutar lantarki a cikin wannan yanayin an rage zuwa maye gurbin yatsunsu, da kuma wani lokacin mating sassa - haɗa sanda head bushings a cikin tsarin da "floating" PP, zobba da sauransu.Zaɓuɓɓukan sababbin yatsu da sauran sassa ana yin su bisa ga girman gyaran gyare-gyare.Alal misali, ga mafi yawan injuna na gida, ana ba da nau'ikan nau'ikan nau'ikan gyare-gyare guda uku, daban-daban ta 0.004 mm (misali, injunan VAZ sau da yawa suna amfani da fil tare da diamita na 21.970-21.974 mm (1st category), 21.974-21.978 mm (2nd category). da 21.978-21.982 mm (kashi na 3)).Wannan ya sa ya yiwu a zabi fil na diamita daban-daban, la'akari da karuwa a cikin diamita na ramukan a cikin sassan mating saboda lalacewa da kuma m.Ana yin ban sha'awa koyaushe don girman gyaran gyare-gyare iri ɗaya, kuma idan lalacewa na sassa ya wuce ƙayyadaddun jeri, to dole ne a maye gurbin su.

A matsayinka na mai mulki, ana sayar da yatsunsu a cikin saiti (2, 4 ko fiye), wani lokaci tare da zoben riƙewa da sauran sassa.

Fistan fil iri-iri da hanyoyin gyara su a cikin fistan

Lokacin gyara ƙungiyar piston tare da fil "mai iyo", babu buƙatar yin amfani da kayan aiki na musamman - shigarwa na sassa a cikin shugabanni da kuma haɗin kai mai haɗawa ana yin ta hanyar ƙoƙarin hannu.Idan yatsa ya canza tare da gyarawa a cikin sandar haɗi, to dole ne ku yi amfani da na'ura na musamman don latsawa da latsa PP (a cikin mafi sauƙi, waɗannan na iya zama bushings da sanduna, amma masu sana'a suna amfani da na'urori masu mahimmanci masu kama da na'ura. ).

A wasu lokuta, shigarwa na PP "mai iyo" a cikin shugabannin kuma ana aiwatar da shi cikin tsangwama, saboda wannan piston yana mai tsanani a cikin ruwa ko wani ruwa zuwa 55-70 ° C kafin shigarwa.Gaskiyar ita ce, fistan aluminum yana faɗaɗa sauri fiye da fil ɗin karfe, don haka akan injin da ba a yi zafi ba, rata tsakanin sassan yana ƙaruwa kuma bugawa ya bayyana.Lokacin shigar da PP a cikin tsangwama, rata yana faruwa ne kawai lokacin da motar ta yi zafi, wanda ya hana tasirin sassa kuma, daidai da haka, bugawa.

Ya kamata a lura da cewa aiki a kan maye gurbin fistan fil na bukatar gagarumin disassembly na engine, don haka shi ne mafi alhẽri a yi su da dace gwaninta ko dogara kwararru.Sai kawai tare da zaɓin da ya dace na yatsunsu da gyaran gyare-gyaren da ya dace, ƙungiyar piston za ta yi aiki da aminci da inganci, tabbatar da babban aikin naúrar wutar lantarki.

Lokacin aikawa: Jul-11-2023