A cikin duk carburetor da injunan allura da yawa, an gina motar mai haɓakawa bisa ga tsari mai sauƙi tare da jigilar injina daga feda gas ta hanyar kebul.Karanta duk game da igiyoyi masu hanzari, nau'ikan su, ƙira da fasali, kazalika da zaɓin kebul, sauyawa da daidaitawa a cikin labarin.

Menene kebul na totur?

Kebul na totur (kebul na kebul na tuƙi, kebul ɗin tuƙin tuƙi, ƙwanƙwasa tuƙi, kebul na maƙura) - nau'in sarrafa hanzari don injunan mai;Twisted na USB a cikin harsashi, ta hanyar da bawul maƙura (a cikin carburetor ko maƙura taro) aka kore daga gas feda.

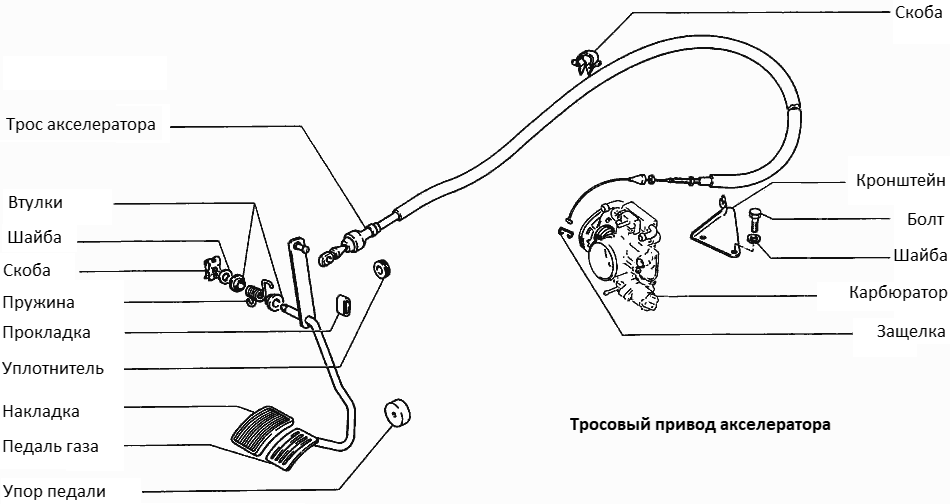

Canje-canje a cikin saurin crankshaft (kuma, daidai da haka, jujjuyawar) na injin ƙonewa na cikin gida ana aiwatar da shi ta hanyar canza ƙarar cakuda mai-iska mai shiga cikin silinda.Canza samar da cakuda mai ƙonewa ana aiwatar da shi ta na'urar sarrafawa ta musamman - mai haɓakawa.Carburetor flaps da sauran na'urori masu alaƙa, bawul ɗin magudanar ruwa da na'urar firikwensin iska mai alaƙa, da sauran su na iya aiki azaman mai haɓakawa cikin nau'ikan injuna daban-daban.Direbobi ne ke sarrafa waɗannan na'urori masu amfani da fedar gas.A cikin carburetor da injunan allura da yawa, an gina motar tuƙi bisa ga tsarin gargajiya ta amfani da injin injin - kebul na totur.

Kebul na totur (sanda mai sauri) yana yin ayyuka da yawa:

● Haɗin injiniya na carburetor ko maƙarƙashiya zuwa fedal gas;

● Tabbatar da buɗewar damper daidai da matakin matsa lamba akan fedarar gas;

● Daidaita matakin buɗewa na damper dangane da kusurwar karkatar da fedar gas;

● Kariya na gaggawar motsa jiki daga mummunan tasirin muhalli, ruwa, gurbatawa, da dai sauransu.

Duk da yawaitar amfani da na'urorin lantarki, kebul na totur baya rasa dacewa kuma ana amfani dashi akan yawancin motoci na zamani.Lalacewa ko karyewar kebul yana haifar da ɓarna ko cikakkiyar asarar iko akan aikin injin, don haka yakamata a maye gurbin wannan ɓangaren da wuri-wuri.Amma kafin ka je kantin sayar da sabon kebul, kana buƙatar fahimtar nau'ikan su, ƙira da fasali.

Nau'i, ƙira da halaye na igiyoyi masu hanzari

Duk igiyoyin gaggawa da ake amfani da su a yau suna da ƙira iri ɗaya bisa ƙa'ida.Tushen ɓangaren shine kebul na murɗaɗɗen ƙarfe (core) tare da diamita har zuwa 3 mm, wanda aka sanya shi a cikin kumfa mai kariya ta filastik.A ƙarshen kebul ɗin, abubuwan da za a haɗa kebul ɗin zuwa na'ura mai haɓakawa da fedar gas suna daidaitawa da ƙarfi.Matsayin irin waɗannan abubuwan na iya zama shugabanni - sassa na silinda na ƙarfe ko ganga mai siffa crimped a kusa da ƙarshen kebul, ko hinges ( hinges) - sassan ƙarfe ko ƙarfe tare da ramukan da ke jujjuya don madaidaicin madauri, fil ko ball.Hakanan a ƙarshen kebul ɗin akwai masu tsayawa - filastik ko mazugi na ƙarfe waɗanda za su iya motsawa cikin yardar kaina tare da kebul, suna hutawa a kan maigidan (ko lefa / sashin injin damper) kuma a cikin harsashi.

Accelerator na USB Drive

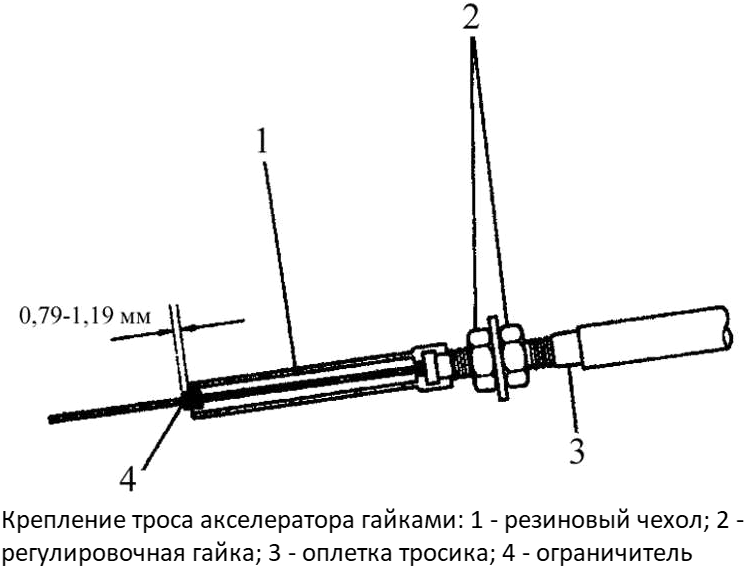

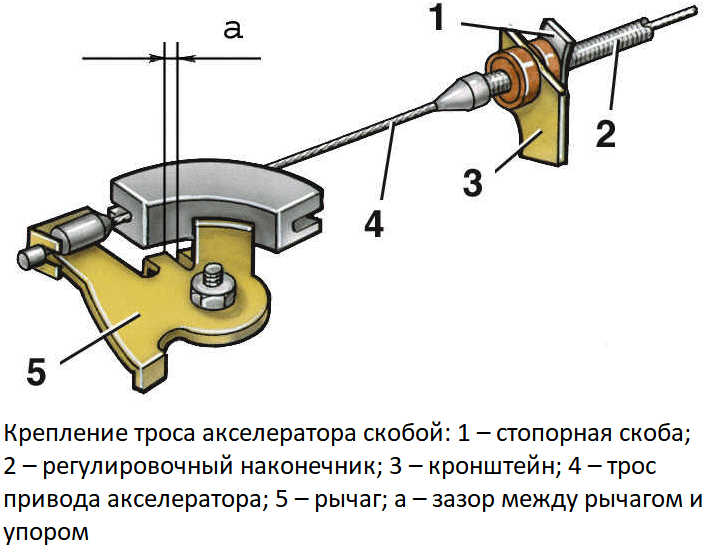

A ƙarshen kullin kariyar da ke gefen haɗa kebul ɗin zuwa fedar gas akwai girmamawa don hawan igiyar zuwa jiki, an yi wannan ɓangaren a cikin nau'i na filastik ko hannun rigar roba, ko kuma wani maɗaukaki mai mahimmanci tare da shi. riga mai zare da goro.A gefen abin da aka makala zuwa mai haɓakawa a ƙarshen harsashi akwai tip ɗin daidaitawa, wanda zai iya samun ƙirar nau'ikan nau'ikan biyu:

● Hannun zaren tare da goro;

● Corrugated hannun riga tare da matsa lamba (s).

A cikin akwati na farko, an yi tip a cikin nau'i na hannun riga tare da zaren waje, wanda aka yi wa kwayoyi guda biyu.An shigar da tip a cikin rami a cikin madaidaicin, inda aka ƙulla shi da kwayoyi - wannan yana ba da duka haɗin kebul na USB da kuma ikon daidaita duk abin da ke motsawa.

A cikin akwati na biyu, ana yin tip a cikin nau'i na corrugated, wanda za'a iya gyara madaidaicin guda ɗaya ko biyu (waya ko farantin karfe).An sanya hannun riga a cikin rami na madaidaicin kuma an gyara shi a gefe ɗaya ko biyu tare da maƙallan - a cikin wannan yanayin, maƙallan suna taka rawar goro, amma ana iya daidaita su cikin sauƙi tare da hannun riga don daidaita motsin hanzari.

Ana iya ba da wasu abubuwa akan kebul: roba corrugations don kare ƙarshen kebul daga gurɓatawa da shigar ruwa, bushings masu kariya don wucewa da kebul a cikin ramuka a cikin sassan jiki, nau'ikan clamps daban-daban, da dai sauransu Lokacin haɗa na USB, na musamman. Ana ƙara mai a cikin kwasfa, wanda ke tabbatar da motsi mai laushi (hana maƙarƙashiya) na tsakiya da kuma kariya daga lalacewa saboda bayyanar ruwa da iskar gas.

An shigar da kebul tsakanin feda na gas da mai haɓakawa (carburetor, taron maƙura), an haɗa ƙarshen kebul ɗin kai tsaye zuwa feda da ma'aunin motsi (zuwa sashin, lever) tare da taimakon shugabanni ko madaukai ( hinges). );Harsashi a gefen haɓaka yana daidaitawa a cikin shinge tare da kwayoyi ko maƙallan, kuma a gefen feda - a cikin rami na jiki tare da taimakon tasha (hannun tallafi).Tare da wannan hawan, yana yiwuwa a matsar da kebul a cikin harsashi da kuma canja wurin karfi daga feda zuwa mai haɓakawa.

Ana daidaita mashin ɗin kebul ɗin ta yadda lokacin da aka danna fedar gas ɗin gaba ɗaya, damper ɗin yana buɗewa sosai.Ana tabbatar da wannan ta hanyar canza matsayi na daidaitawar tip na kebul dangane da sashi, wanda ke haifar da canji a cikin bugun na USB.Tare da daidaitaccen daidaitawa, lever / sashe na damper, lokacin da aka buɗe cikakke, ya tsaya a kan iyaka da ƙarshen tip ɗin daidaitawa ko bai kai shi ba.Idan ba daidai ba daidai ba ne (tip ɗin yana da tsayi sosai zuwa ga mai haɓakawa), lever / sashin yana hutawa ta hanyar iyaka a ƙarshen tip ɗin daidaitawa lokacin da damper ba a buɗe ba - a cikin wannan yanayin, injin ɗin ba ya samun cikakken iko. lokacin da feda ya cika tawayar.Tare da wannan gyare-gyare, tsawon na USB (core) ko da yaushe ya kasance m, kuma kawai hanyarsa yana canzawa, a cikin wannan yanayin babu buƙatar sake haɗawa da haɗa kebul ɗin, wanda ke ƙara yawan aminci da aminci na tuƙi.

Ya kamata a lura da cewa akwai tagwayen igiyoyi masu sauri, waɗanda ake amfani da su sosai akan babura da motoci da yawa.Tsarin, wannan ƙungiya ce ta igiyoyi guda uku waɗanda ke da madaidaicin ma'amala na yau da kullun, ɗaya daga cikin igiyoyin an haɗa su zuwa madaidaicin feda / maƙura, kuma biyu zuwa masu haɓakawa (misali, ga masu dampers na wasu babur biyu-Silinda) ko sauran sassa.Yawancin lokaci, wurin reshe na igiyoyi yana rufe a cikin akwati na filastik ko akwati wanda za'a iya cirewa don kulawa ko gyarawa.

A cikin fasaha, zaku iya samun wasu nau'ikan igiyoyi masu hanzari, amma ƙirar su da ka'idodin aiki sun yi kama da waɗanda aka bayyana a sama, kuma bambance-bambancen kawai a cikin wasu cikakkun bayanai da fasali na aiki.

Kebul mai sauri biyu

Yadda za a zaɓa, maye gurbin da kula da kebul na hanzari

A lokacin aikin mota, kebul na totur yana fuskantar manyan nauyin inji, dumama da sanyaya, ruwa mai ƙarfi da iskar gas, da dai sauransu - duk wannan yana haifar da lalacewa, lalata, cunkoso ko fashewar sashin.Ya kamata a cire kebul mara kyau kuma a duba, kuma idan ba zai yiwu a gyara ɓarna ba, maye gurbin gaba ɗaya.A yau, igiyoyi ba su da ƙarancin wadata, don haka yana da ma'ana don gyara su kawai lokacin da ake yin wedging (matsalar an warware ta ta hanyar ƙara man shafawa zuwa harsashi mai kariya), kuma idan akwai lalacewar injiniya, yana da kyau a canza su - wannan shine duka biyu. sauki kuma mafi aminci.

Don maye gurbin, ya kamata ka ɗauki nau'in kebul ɗin da aka ɗora akan motar a baya, kuma ga motocin da ke ƙarƙashin garanti, dole ne ka yi amfani da sassan takamaiman lambobi.Idan ba zai yiwu ba don siyan kebul na totur na asali, to, zaku iya samun analogue - babban abu shine ya dace da tsayi (duka kebul ɗin kanta da harsashi dole ne su sami ɗan tsayi) kuma a cikin nau'ikan tukwici.

Dole ne a yi maye gurbin kebul ɗin daidai da umarnin don gyara motar.Gabaɗaya, wannan aikin yana da sauƙi: kuna buƙatar cire haɗin shugabanni ko hinges daga mai haɓakawa da feda, sassauta kwayoyi ko cire maƙallan daga tip ɗin daidaitawa, kuma cire haɗin tasha daga gefen feda.A wannan yanayin, yana iya zama dole don wargaza matatun iska, cire bututu da sauran sassan shiga tsakani.An shigar da sabuwar kebul ɗin a tsarin baya, yayin da ake daidaita abin tuƙi.Don daidaitawa, dole ne ka danna fedal ɗin gas gabaɗaya (hanyar mafi sauƙi don yin wannan aikin shine tare da mataimaki), kuma ta hanyar canza matsayin tip ɗin daidaitawa (cire cikin ko kwance goro, ko canza matsayin maƙallan) zuwa tabbatar da cewa damper ya bude sosai.Ana iya yin irin wannan gyare-gyaren lokaci-lokaci yayin aikin mota na gaba.

Tare da madaidaiciyar zaɓi, sauyawa da daidaitawa na kebul ɗin, tuƙi mai sauri zai yi aiki da dogaro a kowane yanayi, yana tabbatar da ingantaccen iko na rukunin wutar lantarki.

Lokacin aikawa: Yuli-14-2023